PPAP Automotive Limited (PPAP) was established in 1978 for manufacturing custom made extrusion products. Today, the company along with its subsidiaries and joint venture companies, deliver value added products to various customers in Automotive and Ancillary Industries.

The company’s core competence is in developing Plastic and Rubber based extrusion systems as well as Plastic injection molding systems for various industries. The company also focuses in developing high precision plastic injection toolings.

The company started its journey of achieving Global Level Excellence in 1985 with the start of the Automotive Business. Over the years the company strives to delight its customers in the Automotive Industry as well as Industrial Products industry. PPAP group is poised to establish itself as a leading product solutions company in the areas of its core competence.

With the advent of electrification of the Automotive Industry, PPAP has established itself as one of the leading manufacturers of Li-Ion based Battery pack solution provider for the 2 wheeler and 3 wheeler industry.

The group has started its journey for achieving ESG standards with the objective of running the operations sustainably and responsibly. Through the company’s CSR activities, there is a constant focus on enriching peoples lives in areas of Environment, Education and Health. The group supports various biodiversity parks by planting and sustaining native trees to improve the environmental conditions.

“We are completely poised with dynamism and resilience to navigate through the volatile environment due to our relentless focus on global level excellence, in each area, of our operations” – Chairman and Managing Director, Ajay Kumar Jain

To be a global level excellence company, with an inspiring work culture, for serving our customers and our society, by exceeding the expectations, of all our stakeholders.

The company believes in benchmarking and implementation of highest standards in various areas of operation like Quality, Environment, Information Security Management System, Health and Safety and Energy. The company continuously challenges these standards and is committed to become a global level company.

The technology transfer agreement focuses on Injection Molded Exterior and Interior products. The relationship started in 2007 and since then both the companies enjoy a mutually beneficial relationship.

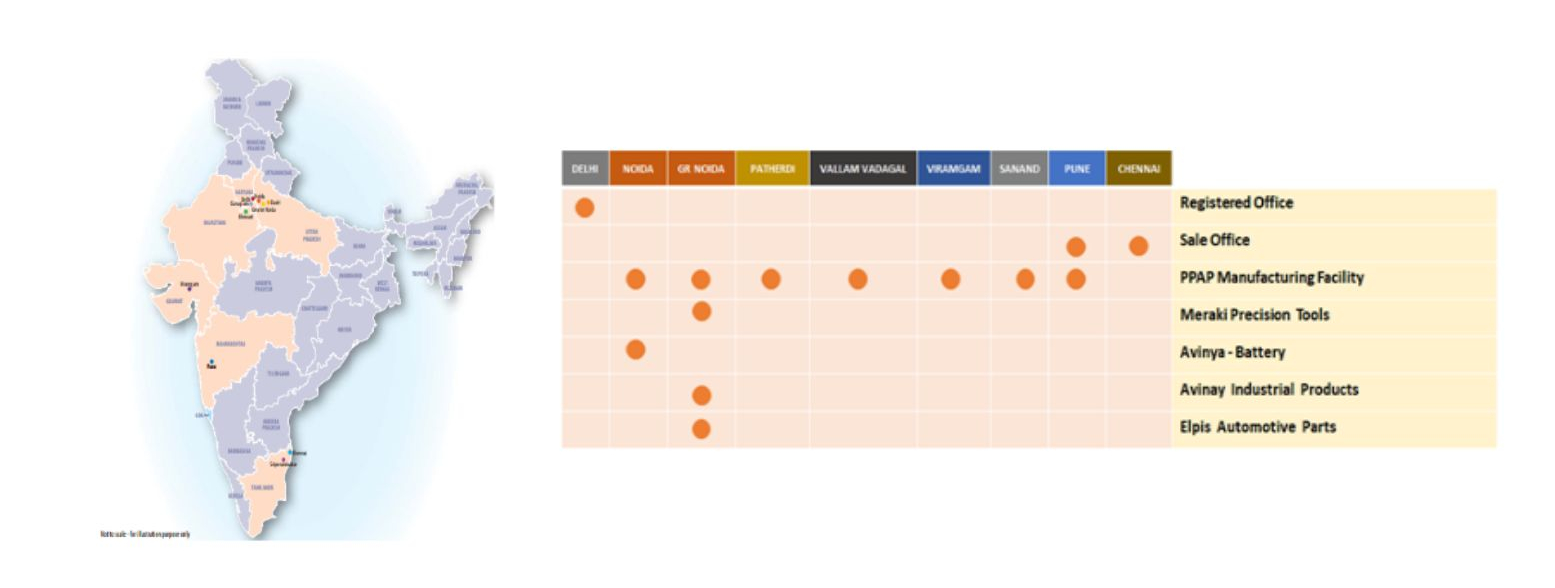

Wholly owned subsidiary established in 2019, engaged in providing lithium-ion battery solutions

Wholly owned subsidiary established in 2025, engaged in providing products for industrial applications

Wholly owned subsidiary established in 2025, engaged in developing plastic injection tooling

The wholly owned subsidiary established in 2019 for trading and distribution of components and automotive accessories.

B-206A Sector 81, Phase II,

Noida 201305

Uttar Pradesh , India

+91 120 4093901